Date marks and storage

Date marking and storage labelling helps determine the shelf life of food products.

Food manufacturers are responsible for determining the shelf life of food products and must be able to substantiate the indicated storage period to enforcement authorities.

Standard 1.2.5 (Information requirements - Date marking of food for sale) of the Food Standards Code (FSS) outlines the form in which packaged foods must be date-marked to indicate their shelf life, eg. a use by statement or a best before statement.

Where, for reasons of health and safety, the consumer needs to be informed of directions for the use of a food, these need to be included on the label.

The Food Standards Code requires the manufacturer to include on the label a statement of any specific conditions required to ensure that the food will keep for the period indicated by the date mark, eg. refrigerate after opening.

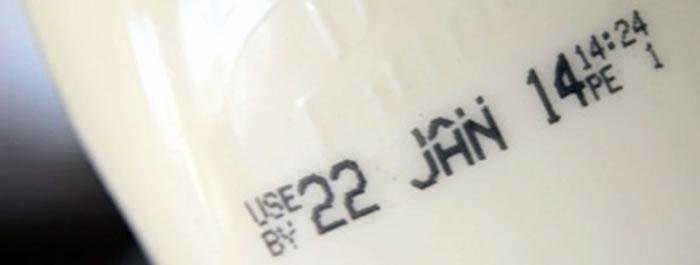

A ‘use by’ date is the date after which the intact, unopened package of food, if stored under the conditions specified on the label, should not be consumed because of health and safety reasons. It is illegal to sell food which has passed its use by date.

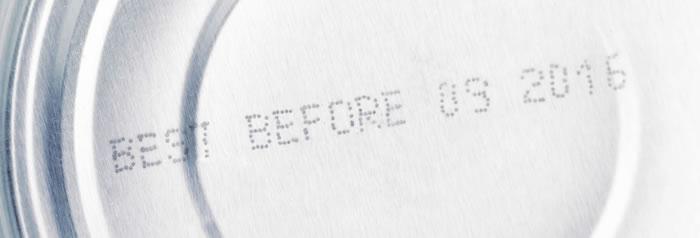

Foods marked ‘best before’ are safe to be consumed provided the food is otherwise fit for human consumption. These foods can be expected to retain their colour, taste, texture and flavour provided they have been stored correctly. Foods marked best before can be sold after that date, provided the food is not deteriorated or perished.

No date mark is needed for:

- when the ‘best before’ date is two years or more

- an individual portion of ice cream or ice confection

- foods contained in a small package (under 100 square centimetres), except where the food should be consumed before a certain date for health or safety reasons

- foods that are exempt from the general labelling provisions of the Food Standards Code.

There is no single factor that determines the shelf life of a product. Microbiological changes, moisture content, chemical or biochemical changes, packaging and physical damage can all affect the shelf life of a product. All these factors need to be considered when determining the shelf life of a food.

There are many methods for determining shelf life. Each method requires a good knowledge of the characteristics of each product and the factors that will affect product quality and safety.

Manufacturers are responsible for determining the shelf life of food products and must be able to substantiate the indicated shelf life to the enforcement authority. Methods for determining shelf life include:

CHALLENGE TESTING

This is a laboratory investigation where a food product is inoculated with one or more appropriate microorganisms. The results are used to determine whether the product formulation, packaging and normal storage conditions of the food can control the growth of pathogens, if present, during the required shelf life. Challenge studies are frequently used for pathogens, but can also be effective in shelf life studies using potential spoilage organisms.

SHELF LIFE STUDY

This is used to assess how long a product can reasonably be expected to keep for, without any significant change in quality. The study is conducted by storing study samples under the same conditions as normal production samples and testing them at various intervals to determine when the product no longer meets the required standard. A separate study needs to be carried out for each type of product. Methods include sensory testing (smell, sight, taste), microbiological testing, chemical testing and physical testing (viscosity, crispness, structure).

ACCELERATED SHELF LIFE STUDIES

These are similar to the shelf life study. The temperature under which the study samples are stored is increased to deliberately increase the rate of deterioration. The results can then be used to estimate a shelf life under normal storage conditions. Similar testing methods that are used in the shelf life study can also be used for accelerated shelf life studies.

PREDICTIVE MODELLING

This involves mathematical equations which use information from a database to predict bacterial growth under defined conditions. Predictive models are specific to particular types of organisms and require information about the physical and chemical characteristics of the product over the anticipated shelf life.

A National Association of Testing Authorities (NATA) accredited laboratory can help with any queries you may have about the methods for determining shelf life. A list of NATA laboratories can be found at www.nata.com.au